Let technology take Over Your Warehouse

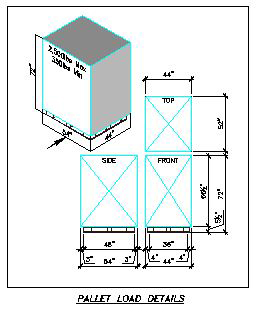

Automated Storage and Retrieval Systems, AS/RS Systems are a very sophisticated material handling systems that utilize the latest technology. It does not make sense for every warehouse storage application, but can drastically change many operations. In order for an automated system to fulfill your distribution needs, examine the rate and storage capacity at which warehouse inventory turns.

After examining product inventory size, storage methods and defining loads you will need to examine how material is currently picked and how accurate your pick rate is. To what degree is your warehouse storage currently automated?

Automated Storage will lend itself to material handling operations with redundancy and rapid picks. If your operation only selects loads a few times a day, automated storage is not the answer to your system needs.

If you struggle with decreasing order picking accuracy and high labor costs then an automated storage and retrieval system might be the answer to your material handling needs. An automated storage and retrieval system can provide controlled access to valuable inventory, increased accuracy and reduced labor costs as intelligence is based on computers and less on human function.

Examine product and warehouse condition – A great application for an automated storage system is heavy material or product that is stored in harsh environments such as freezers. Warehouses with risk to workers will show tremendous increases in productivity with fewer worker’s compensation claims.

Be aware that Automated Storage and retrieval Systems are a large investment and the ROI of implementing the system can be a major time investment. There is no perfect fit for every fulfillment operation, but technology advancements occurring are making AS/RS systems more affordable than ever.

System Highlights:

Automated Storage and Retrieval Systems an take your warehouse to the next level if you are willing to invest in a well-designed system.

If getting and keeping labor is a worry for your operations, AS/RS offers a solution because automation replaces laborers

AS/RS systems can increase warehouse safety by removing the human level of distraction, fatigue or mistakes

Reduce damages by improving workflow and operations

As real estate prices increase, the smaller footprint of an AS/RS system can help pay for the up-front investment

Use the technology of an AS/RS system to drastically improve inventory control

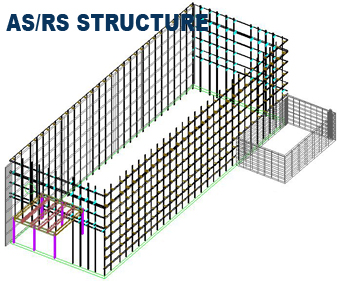

The benefits of a narrow aisle system such as AS/RS lie in the minimal space required and the reduced labor needed for material storage and retrieval. Let UNARCO engineering improve your warehouse productivity. Hazardous worker environments such as freezers, can also be adapted for automated storage and retrieval systems.

For more photos of AS/RS systems view UNARCO AS/RS Photo Gallery.

Initial investment helps save on long-term costs

Software and computer technology will allow for continuous improvement in an AS/RS application and may even offer a competitive advantage. Let technology locate the product and bring it to the worker.

In order for an AS/RS system to become the right choice, you will need to make sure that there is a positive impact on the bottom line. High throughput and improved inventory accuracy can easily make this decision a slam dunk to improve profitability. Product can get in and out of the warehouse faster and this will lower the cost of each pick.