Worksheets & Data Sheets

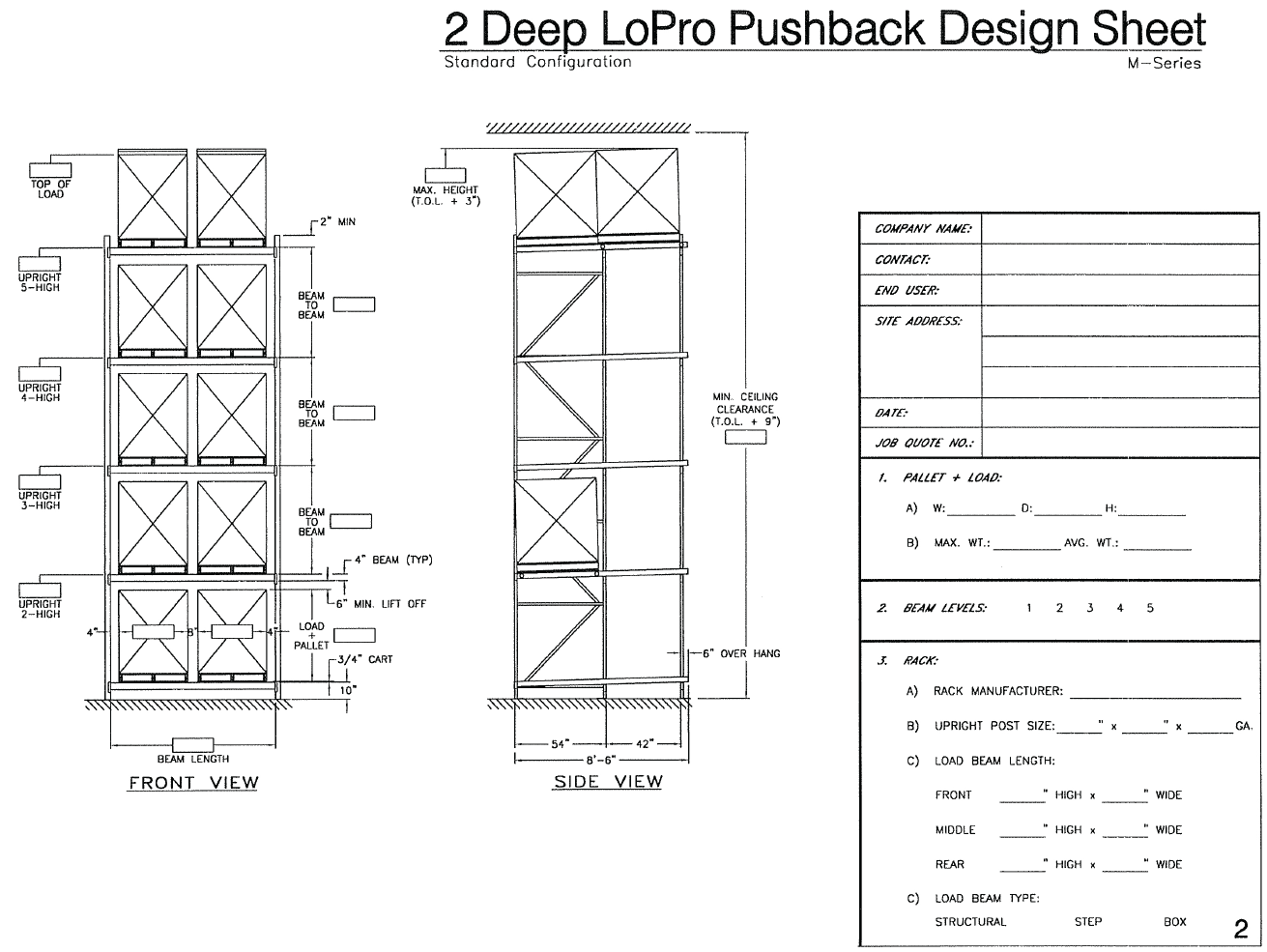

UNARCO’s Push Back Rack can be configured for any size pallet and any weight capacity. Use the sheets above to help design a Push Back Rack system that will meet your specific warehouse criteria. Fill in the Push Back Data Sheets with specific information about pallet size, condition, clearances, and product weights and dimensions. Help us guarantee that your new Push Back Rack design will increase warehouse storage efficiency and pallet storage density.

It is very important to help design the most economic system that collects all pallet rack information, including beam levels, beam lengths, upright height sizes, and whether the pallet rack system will be manufactured using a structural steel or roll-formed rack. With UNARCO’s large range of manufacturing abilities and engineering experience, a new system may be more economical than you imagined. Because all components are manufactured and assembled in-house, and the pallet rack and cart and rail system ship from one location, a cost-effective design can save any warehouse money with increased efficiency.

Regardless of your system’s depth or pallet size, UNARCO can use gravity and ingenuity to improve warehouse throughput.

View photos of Push Back systems in the UNARCO Push Back Gallery.