Carton Flow Rack – Rhinodeck Full-width Roller System

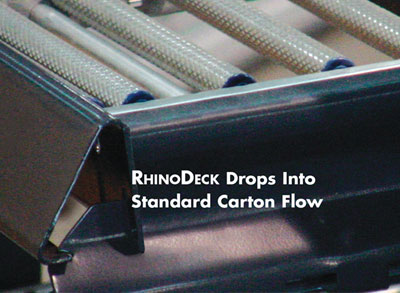

RhinoDeck is a Full-Width Carton Flow Roller system, which takes away maintenance headaches. Manufactured with the same durability as RhinoTrac but with a smaller 1.1″ high profile, RhinoDeck will fit into any existing carton flow rack system. The easy installation requires no hardware and the damage resistant full-width aluminum rollers provide the gravity flow you need in active applications.

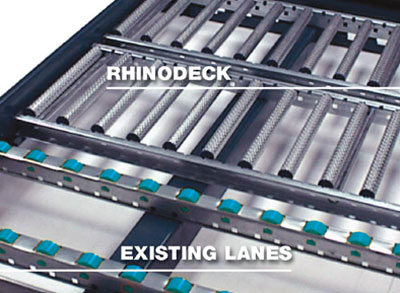

RhinoDeck carton flow rack will work with nearly any manufacturer’s carton flow system to replace individual carton flow tracks with a full-width conveyor option for years of maintenance-free operation.

RhinoDeck provides better product feed and more load capacity than traditional carton flow racks. In performance tests, when placed side-by-side with traditional plastic wheel carton flow rack systems, RhinoDeck's full-width roller units held up over ten times better. This increased durability will save you money on maintenance costs and alleviate the worries of individual carton flow track replacement.

Fully assembled RhinoDeck units simply drop into the racking system and rest on existing supports. Special ties can be inserted to fit with any other manufacturer’s carton flow rack product and even most older carton flow rack systems.

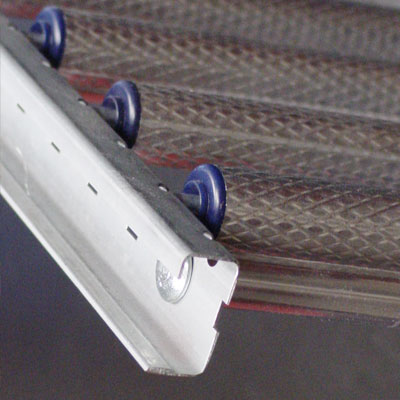

Split-case or full-case picking are easy with RhinoDeck’s sturdy, durable rollers. Sloped shelves and the smooth flow of .75″ diameter diamond embossed rollers move product to the picking position using gravity flow. This means there are no electrical components to require repair or system shutdowns.

RhinoDeck lanes will work with both UNARCO styles of carton flow rack – KPICK Kingway, welded shelf and UPICK knock-down, component shelving units. The low-profile lanes will drop into nearly every carton flow shelf on the market for an instant upgrade to maintenance-free operations.

There is no better answer to your carton flow rack needs than RhinoDeck full-width roller conveyor lanes. Whether you are trying to fix a poorly functioning warehouse facility or provide a new installation that will last for years to come, RhinoDeck is the most cost-effective answer for any carton flow rack requirement.

For more photos of the RhinoDeck Carton Flow Rack, view the UNARCO RhinoTrac Photo Gallery.

System Highlights:

RhinoDeck Carton flow with full-width aluminum rollers provides reliable product flow in high SKU count warehouses.

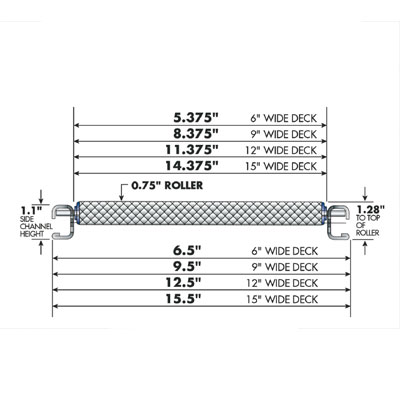

Sturdy 1.1" high side channels

0.75" diameter rollers

Rust resistant aluminum rollers

Heavy-duty bushings for superior roll

Free-flowing axles for maximum carton flow

RhinoDeck aluminum roller carton flow provides excellent box support with full-width lanes and sturdy construction. For low-profile carton flow, no one has more options than UNARCO. Plastic wheel Dura-Flo D2, pictured at right with RhinoDeck, provides the most capacity in a low-profile carton flow shelf in the industry.

For more photos of Rhinotrac and RhinoDeck systems, view the UNARCO RhinoTrac Photo Gallery.