Rhinotrac Carton Flow Rack Roller System

RhinoTrac Carton Flow Rack is the answer to carton flow maintenance headaches. Full-width rollers in pre-assembled units install with ease on any pallet rack manufacturer’s product. RhinoTrac is manufactured at UNARCO to ship with the rest of your carton flow rack. RhinoTrac requires no added on-site hardware and the damage resistant full-width aluminum rollers provide the flow you need in very active carton flow applications.

Fully assembled RhinoTrac carton flow rack units arrive with brackets attached ready to drop into any warehouse storage pallet rack bay.

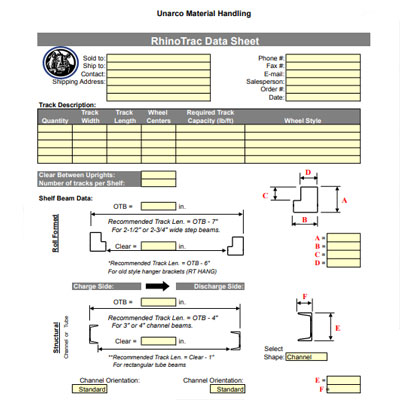

Pre-assembled RhinoTrac carton flow rack units simply drop into the carton flow rack system with integrated brackets for slope adjustment. Brackets are pre-installed on the RhinoTrac units and may be adjusted on-site to gain the proper shelf pitch required. Once RhinoTrac is installed, the tracks rest below the pallet rack beam level in the front for maximum storage and a useful product stop.

Heavy-duty aluminum rollers take the beating your boxes and constant movement give. The versatile RhinoTrac carton flow rack units will fit into all pallet rack manufacturer’s products and will even install on structural racking with the use of an easy-to-install structural pallet rack bracket.

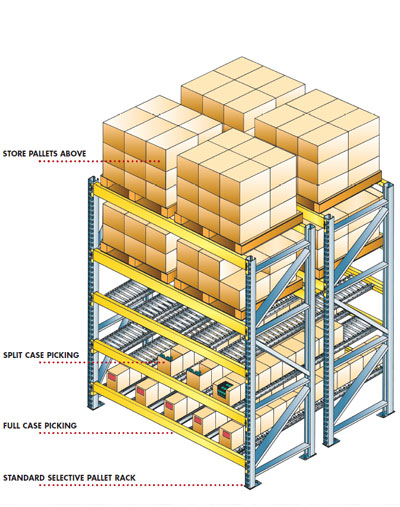

Split-case or full-case picking can be done by adding RhinoTrac units to any pallet rack application, and full pallets can even be stored above. Utilize the full vertical stocking space and improve efficiency by storing pallets and cases within the same bay.

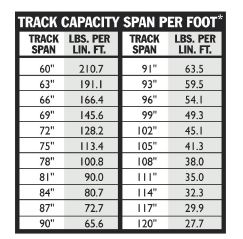

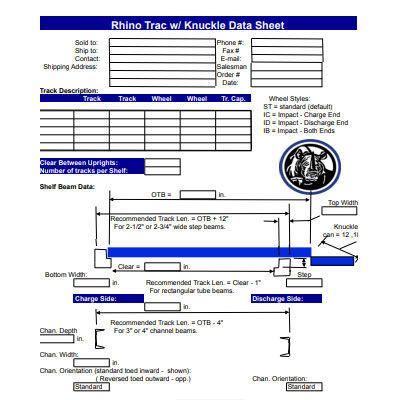

Let UNARCO engineer a RhinoTrac carton flow rack system to improve efficiency in any warehouse storage application for any track capacity. From simple drop-in carton flow lanes to complicated pick module systems. For lighter loads, UNARCO manufactures RhinoDeck carton flow rack.

For more photos of RhinoTrac Carton Flow Tracks, view the UNARCO RhinoTrac Photo Gallery.

System Highlights:

RhinoTrac Heavy-Duty Carton Flow can provide any gravity flow project with a heavy-duty full carton support option to help warehouse efficiency.

Optional Tilt Trays available to angle product at the picking point

Knuckle shelves available with integrated box stops

Create a more ergonomic workplace with Knuckle Shelves and Tilt Trays

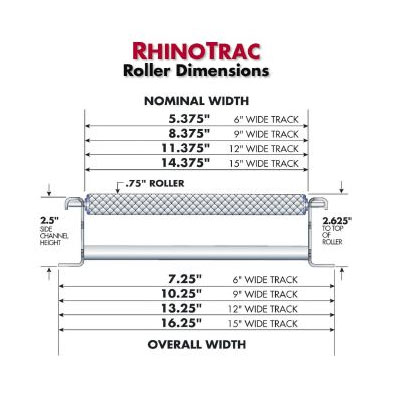

Roller widths available in 6", 9", 12", and 15" wide lanes

Sturdy aluminum rollers are less prone to damage from dropping cartons

Any pallet racking system can easily be converted to carton flow with the addition of RhinoTrac lanes which drop right into pre-existing rack with no tools needed. Sturdy end brackets will work with both structural rack and roll-formed racking on any manufacturer's beam. If your warehouse or distribution center needs heavy-duty flow with better box support, RhinoTrac is the answer for years of maintenance-free carton flow.

For more photos of RhinoTrac Carton Flow systems, view the UNARCO RhinoTrac Photo Gallery.