Nested Carts and Gravity Flow Pallets

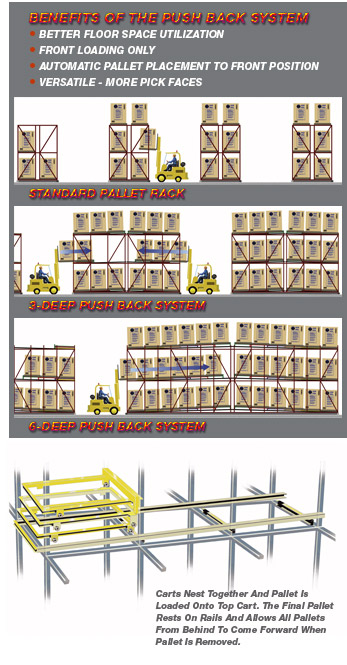

The Push Back Rack system offers many benefits, including multiple carts and the highly engineered nesting manner in which these carts glide pallets into position. Simple push back rack applications that are two to three pallets deep operate in the same manner as a six-deep installation.

The LIFO system pushes pallets forward so forklift operators never enter the rack. Pallets rest on carts that are moved to the picking position on stainless steel wheels by gravity. The push back rack can be located against a wall for a single-sided system or in a center aisle for a double-sided system.

The carts nest on top of each other and slide back one pallet position when a new pallet is added. Each pallet has its own cart, and the last pallet will simply rest on rails running the depth of the bay. When the front pallet is removed, the next pallet slides forward to the picking position automatically using gravity.

Push Back Rack provides all the density of a drive-in system without needing to drive into the rack. This feature helps maintain the pallet rack system and holds damage to a minimum.

Carts use minimal vertical space within the bay because they nest together and flow forward. Even a six-deep Push Back Rack cart stack uses only 6-1/4″ vertical bay height. This low profile leaves plenty of vertical storage area for pallets.

When pallets are unloaded, all pallets flow forward one position on the inclined rails, and the operator can select the next pallet until the push back lane is empty. This creates an obvious advantage of less damage as pallets are stored safely within the system, but also allows for automatic stock rotation of pallets.

Push back wheels are designed to flow even in harsh freezer environments and cold storage areas.

System Highlights:

Push Back Racks provide dense storage with automatic stock rotation fed by gravity – the perfect solution for many industries, including:

Automotive

3PL Facilities

Food and grocery distribution

Retail distribution

Manufacturing and plant facilities

The Push Back concept seems simple, but the highly engineered carts and specialized wheels in a UNARCO system make pallet placement reliable and stock rotation automatic. The inclined rails made of structural steel and the roll-formed, durable carts are easy to assemble and durable for a long lifetime. Our engineers can help you get the right pitch to flow your product consistently to the aisle-picking position, and low-profile nesting carts ensure you have the storage clearance needed.

For more photos of Push Back systems, view the UNARCO Push Back Photo Gallery.

Engineered Carts for Any Application

Special carts can be developed for unstable or damaged pallets, and Push Back Rack carts can be color-coded so that operators can get a full look at how many pallets are in the bay when it is densely loaded.

It only may seem complex, but Push Back Rack is a very versatile and automatically functioning system engineered before it arrives on your site, with easy and fast installation. For more photos of Push Back Rack Systems, view the UNARCO Push Back Rack Photo Gallery.