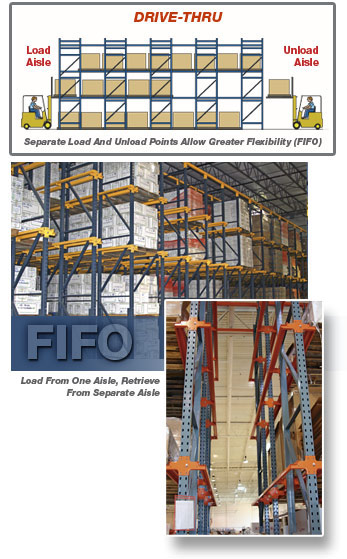

Drive-Thru—For Date-Sensitive Products

Drive-Thru Rack Systems are differentiated from Drive-In systems because they have a separate entry/exit point. With Drive-Thru rack, product is rotated in a FIFO method, making it more suitable for pallets that are date-sensitive. The first pallet loaded on the rail system will be the first pallet removed from the opposite end of the system.

Various styles of Drive-Thru Rack layouts can be adapted to your warehouse space requirements. Unlike Drive-In Rack, Drive-Thru Rack will always require an additional aisle that eliminates some pallet locations and creates a less dense storage than Drive-In Rack. However, Drive-Thru is more flexible for product and inventory rotation.

The advantage of a Drive-Thru Rack system is the efficient manner of separating loading and picking aisles. Since stock is rotated automatically, pickers do not have to handle pallets more than once and are always assured of picking the first pallet placed in the system. This efficient design can also result in less rack damage as drivers do not have to enter the lanes as frequently for product removal.

Any high volume, low SKU count warehouse can immediately benefit from a Drive-Thru rack application by moving pallets closer together and using vertical space. Pallet type and condition are important in any Drive-Thru system because of limited bottom support.

Let UNARCO engineers design the perfect rail system or Structural Drive-Thru Rack system to meet your warehouse storage needs. A Drive-Thru racking system can be as durable as needed by adding safety protection accessories to protect the pallet rack from drivers entering and exiting the Drive-Thru system.

System Highlights:

Drive-Thru Rack systems provide extra clearance for forklift trucks to drive into the rack and should be designed specifically for pallet type.

Access from both sides of the rack

First-In-First-Out (FIFO) stock rotation

Perfect for dated and time-sensitive products

Increased density of pallets to decrease warehouse footprint

Highly customizable system for varied pallet heights

Drive-Thru Rack Systems must be designed specifically for product and pallet type. All aspects of the system must be evaluated by qualified engineers. This is important not only for design purposes involving pallet types and loads, but also to ensure a strong understanding of inventory rotation expectations and product expiration dates.

For more photos of Drive-Thru systems, view the UNARCO Drive-Thru Photo Gallery.

Safe Drive-Thru Applications

All operators in a Drive-Thru Rack System need to adhere to strict safety guidelines because of the tight tolerances of the pallet rack and limited operating space. Any damage to a Drive-Thru Rack System should be reported immediately and the pallet rack should be repaired or replaced.

Whatever your warehouse space allocation, both Drive-In and Drive-Thru racking can provide extremely dense storage for pallets at a very affordable cost.

For more information on Drive-Thru Rack, view the UNARCO Drive-Thru Photo Gallery.