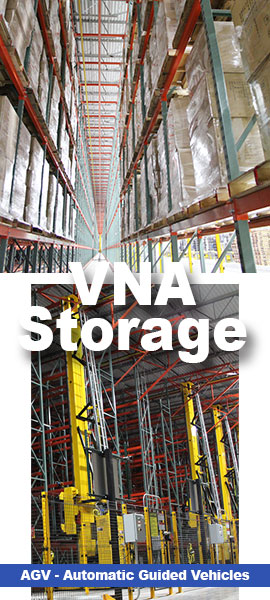

Very Narrow Aisle Storage

UNARCO creates storage solutions for sophisticated Very Narrow Aisle (VNA) warehouse configurations which utilize Automatic Guided Vehicles (AGVs) to place and retrieve pallets in very dense racking areas. The accuracy, speed, and reach of these VNA fork trucks allows for smaller warehouse aisles and maximum use of space. The VNA Systems reduce labor costs, product damage, and picking errors.

UNARCO Pallet Racking is the heart of the VNA system, providing tight tolerances and strong connections to help maintain every available inch of storage capacity. By eliminating the warehouse aisles, a VNA system can double pallet storage and high-reach fork trucks can utilize every inch of vertical warehouse space.

The flow of pallets is controlled by software which ensures the VNA system will render real-time control over the entire warehouse storage process. This allows for tighter inventory control, reporting, and monitoring to maximize throughput of pallets through the system.

The AGV units are portable and increase productivity because they move at a high rate of speed for pallet selection. The accuracy and speed of these vehicles, when combined with the minimal amount of space needed for pallet placement and picking, allows warehouse owners to service thousands more pallets in the same building footprint.

The VNA solutions provide the same dense pallet storage as an AS/RS System (Automated Storage and Retrieval System) with more flexibility. Any sophisticated AGV can take conventional storage and staging and create a productive flow of activity within the VNA System that will sometimes even use existing pallet rack.

System Highlights:

VNA - Very Narrow Aisle Storage Systems increase storage space by moving the pallet rack close together.

Standard pallet rack that is compacted into a smaller area

High-density storage system

Increases the warehouse capacity without adding square footage

Warehouse optimization by decreasing aisle space

Special forklifts designed for narrow aisles and tall storage rack pick product

The VNA applications use swing reach trucks, order pickers, and side-loader forklifts that can access stacking up to thirty feet high. Very Narrow Aisle Systems can be optimized by implementing wire guidance systems to help fee operators from steering responsibilities. This can also help decrease product damage and driver injuries, creating a safer warehouse.

Narrow aisles increase warehouse efficiency by creating shorter travel paths and allow for nearly 70% more product storage in the same warehouse square footage area.

For more photos of AS/RS systems, view the UNARCO AS/RS Photo Gallery.

Smaller Aisles - Bigger Storage

Many VNA Systems are also called “dark systems” because there is limited lighting within the pallet rack area since workers are not present this space, and the AGVs do not require a lit system.

For more photos of VNA (Very Narrow Aisle) Storage view the UNARCO Pallet Rack Photo Gallery.