Rack Repair Options

Pallet rack repair kits from UNARCO are designed to be extremely versatile because there are numerous rack manufacturers and many different pallet rack configurations and types of rack damage. Straight-leg or sloped-leg designs can be engineered and configured to install onto any RMI rack manufacturer’s pallet rack.

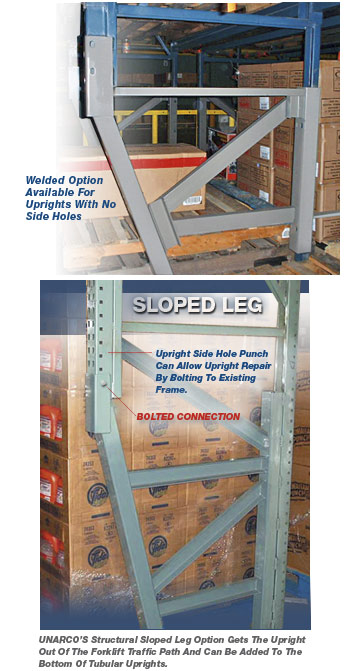

The simple solution to a quick-install is the bolted option. Repair kits that are bolted to frames do not present the fire-hazard of welding or require specialized welding technicians. Repair frames can be bolted to existing frames that are punched on the sides. The slotted side holes in repair kits line up with side punching in standing uprights and securely attach the kit to the existing rack upright frame.

Special pallet rack repair kits can also be developed to bolt through the front holes in the existing rack upright. UNARCO engineering has created custom pallet rack repair kits for nearly every pallet rack manufacturer in America.

However, there are circumstances when there is no side punching in the existing uprights to attach the repair kit to and welding becomes the clear pallet rack repair option. A welded option uses the same bracket on the repair kit attachment but is welded to the existing frame instead.

Both applications are safe and will increase the longevity of the pallet rack system; however, the welded option requires additional equipment and field personnel with welding experience. UNARCO has a long list of trained installers who are able to safely restore your system with minimal interruption regardless of the application you choose.

System Highlights:

Pallet Rack Repair Kits should only be installed by professionals who are certified and trained.

Bolted repair kits are easier to install than welded

Welded pallet rack repair kits are more costly and typically more custom designed

Seismic and engineering design should always be considered when designing a rack repair kit

Welded rack repair kits should only be installed in well-ventilated areas because fumes can be harmful

Welded rack repair kits should only be installed in well-ventilated areas because fumes can be harmful

There are many considerations when welding pallet rack repair kits inside a warehouse. Some of the things to consider include fire, weld contamination, operating temperature, welder certification and the training of the installers. The RMI has put out a safety bulletin with guidelines for welding pallet rack repair kits in warehouses and distribution centers.

For more photos of Pallet Rack Repair, view the UNARCO Pallet Rack Repair Gallery.

Welded Pallet Rack Repair Comes with Risks

Once pallet rack damage is identified, the more affordable option is generally a bolted repair kit. Please beware of maintenance personnel attempting to fix a pallet rack without a proper repair kit and by simply welding parts together instead. It may seem like a logical reinforcement, but qualified engineers should always design a fix for pallet rack damage.

To see more photos of pallet rack repair, visit our Pallet Rack Repair Portfolio or view our Pallet Rack Repair Brochure.